Where Does Oil and Natural Gas Come from?

- Oil and natural gas are organic materials formed from decayed plants and animals that have been converted to fossil fuels by exposure to heat and pressure in the earth’s crust over hundreds of millions of years.

- Oil typically exists in the liquid state in natural underground reservoirs characterized by the type and permeability of the geologic rock formations. Most of the oil produced from unconventional (horizontal) wells in Texas comes from tight (low permeability) shale formations.

- Natural gas exists as a gas at atmospheric conditions. A well’s primary production may be either natural gas or oil and may have varying amounts of each.

How is Oil and Natural Gas Produced?

- Wells in North America produce oil and natural gas through drilling conventional (vertical) and (usually) unconventional (horizontal) wells. Conventional vertical wells are drilled vertically down to a reservoir of oil and natural gas. Unconventional horizontal wells are drilled vertically and are turned horizontally to run along the formation at depth. Wells are then typically completed through hydraulically fracturing the formation. Typically, produced fluids are a combination of oil, natural gas, and produced water that are separated at a production facility.

- Unconventional horizontal wells are drilled vertically and are turned horizontally to run along a target rock formation at depth. Horizontal wells are then typically completed through hydraulically fracturing the formation. Hydraulic fracturing uses pressure to open cracks in a tight formation, such as shale, to allow for the release of trapped oil and natural gas.

- The oil and natural gas flow together to the surface and are separated by vessels at oil and gas facilities using pressure and temperature settings.

What is Hydraulic Fracturing or “Fracking”?

- Hydraulic fracturing or “fracking” is a completion technique necessary to extract productive quantities of natural gas and oil from tight geologic formations. Hydraulic fracturing fluid is injected at rates and pressures designed to fracture the rock and enable oil and gas to flow to the wellbore. Although commonly a mixture of water, fracturing can use chemicals in small quantities, and proppant (e.g. sand). More detailed information on the makeup of various hydraulic fracturing fluids can be found at Frac Focus.

- Hydraulic fracturing is designed and controlled to fracture the target formation, which is isolated from other formations by steel casing and cement. Wellbore construction is strictly regulated to protect groundwater formations.

What is Natural Gas Composed of?

Below is a non-exhaustive list of some of the most familiar components.

| Component** | Domestic Use | Industrial Use |

| Methane (CH4) |

|

|

| Ethane (C2H6) |

|

|

| Propane (C3H8) |

|

|

| Butane

(C4H10) |

|

|

| Octane (C10H22) |

|

** Number under the C denotes number of carbon atoms; Number under the H denotes number of hydrogen atoms

How is Oil and Natural Gas Transported?

- Pipelines are the main method of transportation for oil, natural gas and fuel in Texas, safely providing dependable, low-cost sources of energy.

- Oil can be loaded onto trucks or railcars for transport or sent through a pipeline.

What are the Benefits of Transporting Oil and Natural Gas through Pipelines?

- Pipelines, like roads, are for public benefit – through them we can access, safely transport, and utilize Texas’s abundant supply of oil and natural gas.

- Using pipelines to transport oil and natural gas improves air quality and safety by reducing the burden on our surface infrastructure, such as roads. A moderate 20” pipeline running 50 miles, for example, can displace 1,650 trucks – reducing congestion, traffic accidents, highway damage, and pollution.

- Depending on economic conditions, conservative estimates covering the period from 2014-2024 indicate that the pipeline industry will contribute more than $374 billion in total economic output, 171,000 jobs sustained and more than $212 billion to the gross state product, as well as $1.5 to $2 billion per year in state and local government revenue. (From the Texas Pipeline Association)

Why Can’t all of the Natural Gas be Sold/Transported to a Natural Gas Processing Plant?

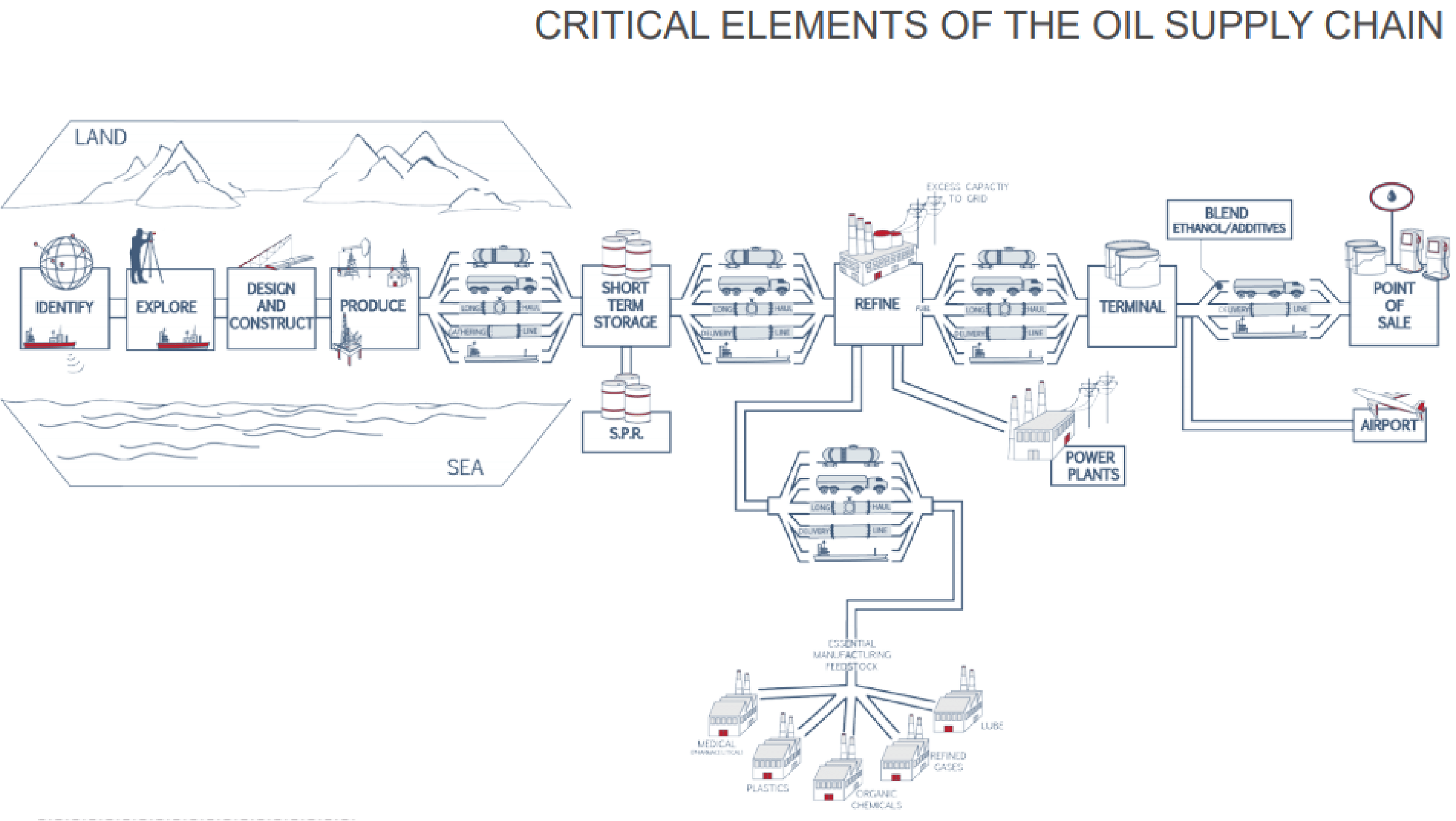

The system of exploration, production, transportation, processing, and distribution is highly complex.

UPSTREAM:

-

-

- The exploration and production sector (i.e. “upstream”) is responsible for producing the wells and securing sustainable transportation of the product to the processing plant.

-

MIDSTREAM:

-

-

- The transportation and/or processing sector (i.e. “midstream” or “gatherers”) segment of the oil and natural gas industry includes pipelines and the processing plants that convert the raw oil and natural gas into useful components.

-

DOWNSTREAM:

-

-

- Petroleum refineries and chemical manufacturing plants (i.e. “downstream”) further refine the product for domestic or industrial uses. Downstream companies may also include local distribution companies, which provide energy (natural gas and electricity) to residential and commercial customers.

- Access and availability of pipelines to transport oil and natural gas may be temporarily constrained or limited at times due to a variety of factors that include, but are not limited to:

- Lack of infrastructure connectivity or availability to a natural gas processing plant (e.g. no pipeline available, delays in authorizations or permitting).

- There is not enough capacity in the pipeline to transport the natural gas to the processing plant.

- The processing plant is down for maintenance or other temporary disruptions.

- The natural gas does not meet the pipeline company’s specifications for acceptance (e.g. gas contains too much hydrogen sulfide, carbon dioxide, oxygen, or water.)

-

What Happens if the Natural Gas Cannot be Sold/Transported to a Natural Gas Processing Plant?

- Sometimes the natural gas associated with the produced oil may not be suitable for sale or alternative re-use options (e.g. fuel on-site.) The gas may not be suitable for sale due to high CO2 content, high H2S content or other issues.

- Natural gas that is not suitable to be sold or used in alternative processing options (e.g. onsite equipment fuel source) can either be vented or combusted (i.e. flared) onsite in accordance with regulation.

What is Venting?

- Venting is the release of natural gas directly into the atmosphere.

- Certain devices at an oil and natural gas facility vent small volumes of gas by design and as part of normal operation. As an example, pneumatic devices can use natural gas to control safety shutdown, fluid level, pressure, and other operational parameters.

- In the event of repair, maintenance, or malfunction (i.e. an upset), a controlled discharge of piping and gas-containing equipment may be necessary to relieve any build-up of pressure. This involves venting natural gas in a manner that is safe and managed. Facilities are designed and operational processes are in place to safely conduct such activities to prevent injury and damage to life, property, and the environment.

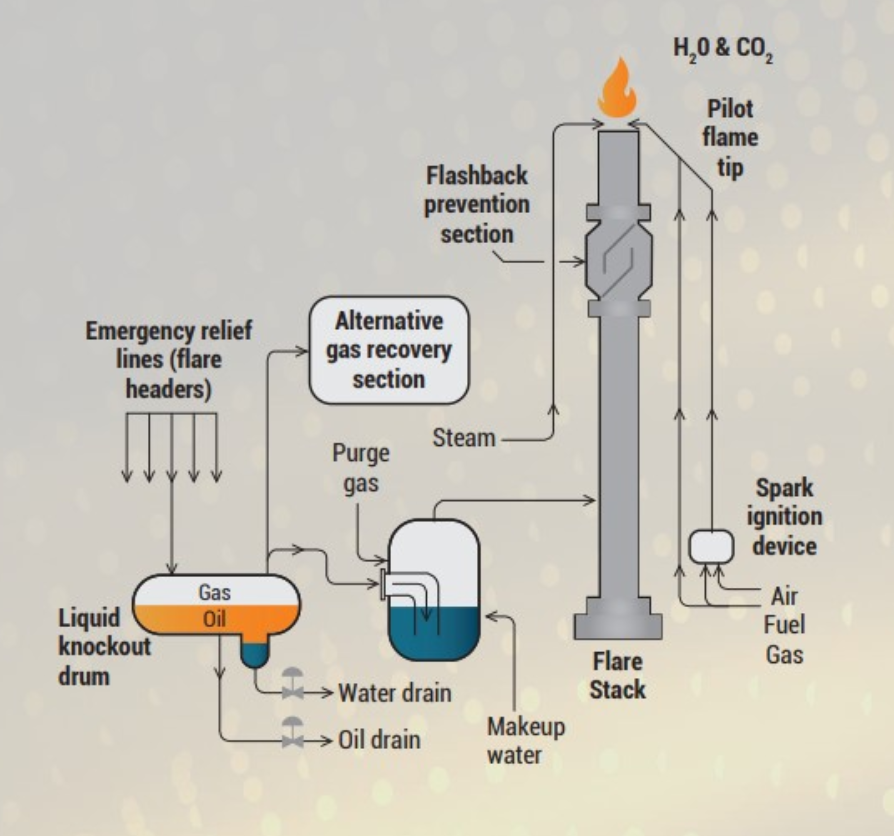

What is a Flare?

- A flare is a combustion device with a pilot and ignitor (similar to furnaces, water heaters, etc.) designed to minimize the amount of pollutants emitted.

What Measures are in Place to Ensure Safety in the Oil and Natural Gas Industry?

The oil and natural gas industry prioritizes safety through measures that include but are not limited to:

-

-

- Engineered safeguards, such as facility design, materials selection, automation, blowdown systems, pressure relief equipment, emergency shutdown systems, flares, hazardous communication labeling, lock-out/tag-out programs, equipment bypass, flame arrestors, monitors, alarms, control devices and redundant safety systems;

- Rigorous inspection and maintenance programs to ensure equipment integrity;

- Extensive employee training, Emergency Response Plans and tabletop drills; and

- Processes that employ standard operating procedures, pre-work hazard assessments, stop-work authority and sharing of best practices.

-

How is the Oil and Natural Gas Industry Regulated?

The oil and gas industry is highly regulated by numerous state and federal agencies, which establish regulations and guidance to govern different aspects of the oil and gas industry, including but not limited to:

-

-

-

- Site selection (i.e. where a well can be drilled taking into account land ownership, terrain, wildlife, proximity to water bodies, etc.)

- Drilling, completion, facility and production design (i.e. what kind of well can be drilled, how the well is drilled, how the well is completed [hydraulically fractured or other], what surface equipment must be installed, the location of that equipment within the pad, how to manage and control production at the surface, etc.)

- Control of air pollutants (i.e. the types, if any, of control devices that need to be installed; the maximum amount of emissions allowed; when, how long, and how much natural gas can be vented and/or flared; the amount (mass) of natural gas that can be emitted, etc.)

- Maintenance, recordkeeping, reporting, and testing (i.e. determination of the frequency and types of testing and maintenance, the frequency and types of records to maintain, reports to submit, identification of all required data contained within said record and reports, participation in inspections and audits, etc.)

- Closure of a well (i.e. the procedures, materials, testing, and documentation necessary to plug and abandon a well, remove equipment, etc.)

- Remediation and restoration of the land (i.e. the process of clearing the wellpad, restoring soil, vegetation, and other pre-well terrain, etc.)

- Pipelines infrastructure and transportation (i.e. the construction of pipeline infrastructure and the transport of energy products through those pipelines, including crude oil, refined products, such as gasoline and diesel, and natural gas liquids.)

-

-

How is the Oil and Natural Gas Industry Regulated by the Federal Government?

Nine state and federal agencies regulate all aspects of oil and natural gas activity, such as well construction and air emissions. Operators that do not follow strict regulations can lose their permit to operate in Texas.

- The United States (US) Environmental Protection Agency (EPA) has primary authority for protection of air quality (as well as their other responsibilities that include oversight of water and waste management) and may delegate authority to a state. EPA has established numerous regulations that are particularly relevant to controlling air pollutants associated with oil and natural gas operations. These include but are not limited to:

-

- New Source Review (NSR) regulations establish permitting requirements and utilization of proper control technologies;

- New Source Performance Standards (NSPS) and National Emissions Standards for Hazardous Air Pollutants (NESHAP) prescribe emission and/or equipment standards for new or modified sources. Where applicable, these standards often have requirements for emissions reduction equipment, monitoring, testing, recordkeeping, and reporting; and

- The Greenhouse Gas Mandatory Reporting Program (GHGRP) requires a comprehensive calculation of CO2 equivalent (CO2e) emissions from a wide variety of sources and activities, including flaring and venting.

-

- In addition to applicable State and EPA regulations, the Bureau of Land Management (BLM) also addresses methane emissions on federal lands through the Waste Prevention, Production Subject to Royalties and Resources Conservation rule that was finalized in 2018.

- Pipelines transporting oil and natural gas are also subject to regulation and oversight by the Pipelines and Hazardous Materials Safety Administration (PHMSA). PHMSA develops, issues, and enforces various safety regulations covering pipeline construction, operation, and maintenance, and conducts pipeline inspections and enforcement activities across the country.

How is the Oil and Natural Gas Industry Regulated by the State of Texas?

Numerous state agencies regulate all aspects of oil and natural gas activity, such as well construction and air emissions. Operators that do not follow strict regulations can lose their permit to operate in Texas.

- The Texas Commission on Environmental Quality (TCEQ) has jurisdiction in Texas over air quality issues, including permitting, compliance, and enforcement.

-

- Permitting can take many forms (e.g. Permit by rule or PBR, Title V permit, or pre-construction authorization) depending on the amount and type of emissions and/or activities anticipated at a facility. As an example, an oil and natural gas operator must obtain the appropriate pre-construction authorization (i.e. permit) before its facility commences operation.

- Permit applications require calculations of emissions from all activities and emission sources found onsite. These are included in a site-wide potential to emit totals that denote the maximum amount of each air pollutant that may be emitted at a site.

- In some instances, companies must also evaluate the best available control technology (BACT) available for the operations conducted at the facility to obtain permit approval.

- Companies are subject to agency inspections and audits, as well as required to submit timely notifications/reports for emissions events that may occur at a site. In this notification, the description, duration, calculations, and emission totals of all air pollutants are required.

- Advanced technology, such as Optical Gas Imaging cameras, are being used to inspect oil and natural gas sites, improving an operator’s ability to identify and take corrective actions.

-

- The Texas Railroad Commission (RRC) regulates the exploration, production, and transportation of oil and natural gas in Texas. The RRC has a statutory role to prevent waste of the state’s natural resources and prevent pollution. In this role, the RRC has jurisdiction over flaring through SWR 32 with respect to the prevention of waste of natural resources.

What are Emissions?

- Emissions are the mass (or mass rate) of air pollutants released into the atmosphere. The mass/rates are derived from volumes via the chemical properties of the natural gas.

- Volumes are typically expressed in units of standard cubic feet (scf). Emissions are typically expressed in pounds, tons, and metric tons. Often, they are expressed as a rate (especially in air permits), such as scf per year or pounds per hour or tons per year.

- Emissions come from a variety of sources and activities on an oil and natural gas facility, including but not limited to the following:

-

- Fuel combustion for engines, flares, and other equipment;

- Heater treater vessels;

- Separation vessels;

- Storage tanks;

- Produced water tanks;

- Fugitive emissions (i.e. piping and piping components);

- Compressors;

- Generators;

- Dehydrators;

- Amine units; and

- Loading of oil and water into trucks.

-

- Emissions from oil and natural gas activities may include, but are not limited, to methane (CH4), VOCs (e.g. propane, butane, octane), hydrogen sulfide (H2S), and particulate matter (PM).

- Additionally, when natural gas is combusted, the by-products of combustion include carbon dioxide (CO2), sulfur dioxide (SO2), water (H2O), nitrogen oxides (NOx), and carbon monoxide (CO).

Are There Different Categories of Emissions?

There are different categories of emissions that state and federal agencies regulate and/or monitor. Listed below are the most common emissions categories in the oil and natural gas industry:

-

-

- Greenhouse Gases (GHG) – Gases that contribute to the formation of carbon dioxide or carbon dioxide equivalents in the atmosphere. The types of greenhouse gases seen in the oil and natural gas industry include methane, carbon dioxide, and nitrogen oxide.

- Criteria Pollutants – Air pollutants for which a federal air quality standard exists. The six criteria pollutants are lead, sulfur dioxide, particulate matter, carbon monoxide, nitrogen dioxide, and ground level ozone. Further, ground level ozone (also known as smog) is formed from chemical reactions of heat and sunlight with NOx and VOCs.

- Volatile organic compounds (VOC) – Hydrocarbons with three or more carbon atoms and that include propane, butane, and octane, among many others.

- Hazardous Air Pollutants (HAPs) – Air pollutants that are known or suspected to cause cancer or other serious health effects, such as reproductive effects or birth defects, or adverse environmental effects. These are also referred to as “air toxics” or “toxic” air pollutants; EPA has officially designated 187 air pollutants as “hazardous.”

- Hydrogen sulfide – is another type of air pollutant found in oil and natural gas operations. Hydrogen sulfide is a naturally occurring colorless, flammable, toxic gas with a foul odor at low concentrations. When burned, hydrogen sulfide is converted to sulfur dioxide, which is preferable.

-

Is there a Difference Between Vented Emissions and Flared Emissions?

- Emissions from flaring pose a lower risk to the environment, compared with vented emissions, as flaring reduces the amount of air pollutants that reach the atmosphere.

- Typical flare efficiency is 98% combustion.

- CO2e (primarily from methane) is reduced accordingly.

What is not included in routine flaring?

Routine flaring does not include flaring for the purpose of controlling emissions (e.g. tanks, dehys) and safety flaring, which is the flaring of gas to ensure safe operations of a facility, or intermittent short duration “event” flaring, such as equipment failure, preventative maintenance, process upsets, and well testing or clean up after initial completion or work over.

What’s the importance of non-routine and safety-related flaring?

Sometimes flaring is necessary for safety, environmental, or emergency situations, due to gas quality, or other non-routine reasons, such as initial well flowback, well servicing, process upsets, gas handling infrastructure malfunctions, maintenance and system outages that at times are weather-related. Gas with H2S is generally required to be flared for safety reasons. Midstream companies, operators, and regulators use a variety of measures to reduce flaring in Texas. Safety flaring is for the safe operation of oil and gas facilities. Non-routine flaring is often unforeseen and typically intermittent and of short duration.

Environmental NGOs have asked Texas to commit by 2025; why has the Coalition committed to a date further in the future?

The Coalition’s goal to end routine flaring by 2030 is the same date as the World Bank’s global goal. Companies need time to test new technologies, adapt, grow, and make the necessary implementations to create longstanding changes.

What action should the RRC take in limiting routine flaring?

The Railroad Commission of Texas’ (RRC) Statewide Rule 32 outlines requirements on flaring. Currently, the agency is reviewing and implementing changes on flaring through its forms, data, and hearings. The Coalition supports the RRC’s more stringent approach to granting exceptions under current provisions of SWR 32. We also support enhanced reporting from operators, which will provide more information to better understand the reasons for flaring. In addition to working closely with the RRC, our operators have already incorporated best practices that will help achieve the goal of reducing and eventually eliminating the practice of routine flaring.

What action should the Legislature take to prohibit routine flaring? Or, when asked to commit this to statute, what is the Coalition’s response?

The Coalition believes that the oversight of flaring can continue to be handled at the regulatory level by the Railroad Commission of Texas and supports the work that the RRC is doing to update its routine flaring regulations. In addition, the Coalition is proud of the voluntary industry-led efforts our members are enacting to limit and end routine flaring, which typically drive the most significant and lowest-cost solutions.

How does the RRC’s jurisdiction over flaring differ from that of the TCEQ?

The Railroad Commission of Texas regulates flaring of gas (Statewide Rule 32) pursuant to its authority to conserve and prevent waste of the State’s natural resources. The Texas Commission on Environmental Quality (TCEQ) regulates emissions of air contaminants pursuant to its authority to protect air quality. Compliance with Statewide Rule 32 does not constitute authorization of the emission of air contaminants associated with venting and flaring. You can read more about this issue here: RRC Notice